Woods Used by Woodcrafter Designs

Alphabetical Listing (to see by wood color, click Here)

Alder, Red – From Coastal western North America. Red Alder tends to be a light tan to reddish brown; color darkens and reddens with age. There is no  visible distinction between heartwood and sapwood. The overall grain pattern and appearance is similar to Birch—though redder than Birch. Red Alder is rated non-durable to perishable regarding decay resistance, and freshly cut logs should be quickly converted into lumber and dried to prevent staining or decay in the wood. Red Alder is the most abundant hardwood in the Pacific Northwest region of the United States.

visible distinction between heartwood and sapwood. The overall grain pattern and appearance is similar to Birch—though redder than Birch. Red Alder is rated non-durable to perishable regarding decay resistance, and freshly cut logs should be quickly converted into lumber and dried to prevent staining or decay in the wood. Red Alder is the most abundant hardwood in the Pacific Northwest region of the United States.

Workability - Red Alder is very easy to work with both hand and machine tools; it sands especially easy. The wood is rather soft, however, and care must be taken to avoid denting it in some applications. Red Alder has excellent gluing, staining, and finishing properties; it also turns well and behaves similar to Black Cherry.

Finishing – oil-based varnishes.

Pricing +

African Mahogany - Found in tropical Africa,

rated as moderately durable but with only moderate to poor insect/borer resistance. Heartwood ranges from pal e pink to a deeper reddish brown, sometimes with streaks of medium to dark reddish brown. Colors darken with age. Quartersawn surfaces exhibit a ribbon-stripe appearance. Common uses are veneer, plywood, turned items, furniture, boatbuilding, and interior trim.

e pink to a deeper reddish brown, sometimes with streaks of medium to dark reddish brown. Colors darken with age. Quartersawn surfaces exhibit a ribbon-stripe appearance. Common uses are veneer, plywood, turned items, furniture, boatbuilding, and interior trim.

Workability -

Generally easy to work, though tearout can be a problem if the grain is interlocked. May stain and react with iron-based fasteners in damp conditions. Glues, turns, and finishes well.

Finishing - oil-based varnishes.

Pricing +

Afrormosia - Afrormosia is found throughout Central and the West Coast of Africa along the Ivory Coast, Ghana, Congo, Nigeria, and Cameroon. The wood  is sometimes referred to as “African Teak,” though it is not closely related to genuine Teak , and it does look somewhat similar to Teak, has similar working and mechanical properties, and is extremely durable in outdoor applications; for these reasons, it's used with a fair degree of success as a substitute for Teak. It has beautiful coloration, which ranges from golden to darker brown, gradually turning to a deep, rich, walnut-like color. It is very durable regarding decay resistance and is also resistant to termites and other insects. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline

in its natural range, and exploitation. In addition to its striking appearance, afrormosia has long been a favorite in Europe for high-grade commercial and residential construction when quality and appearance, rather than cost, have been design objectives and a uniform,

rich look is desired. A first-class cabinet and furniture wood, it is not well known in the United States, but admired by all those who know it.

is sometimes referred to as “African Teak,” though it is not closely related to genuine Teak , and it does look somewhat similar to Teak, has similar working and mechanical properties, and is extremely durable in outdoor applications; for these reasons, it's used with a fair degree of success as a substitute for Teak. It has beautiful coloration, which ranges from golden to darker brown, gradually turning to a deep, rich, walnut-like color. It is very durable regarding decay resistance and is also resistant to termites and other insects. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline

in its natural range, and exploitation. In addition to its striking appearance, afrormosia has long been a favorite in Europe for high-grade commercial and residential construction when quality and appearance, rather than cost, have been design objectives and a uniform,

rich look is desired. A first-class cabinet and furniture wood, it is not well known in the United States, but admired by all those who know it.

Workability - In nearly all regards, Afrormosia is easy to work with both hand and machine tools, though surfacing boards with interlocking grain may cause tearout. Other downsides include a slight blunting effect on cutting edges, and the development of dark stains if left in contact with iron in damp conditions. Afrormosia turns, glues, stains, and finishes well.

Finishing – oil-based varnishes

Pricing +++

Ash, White – From Eastern North America. The heartwood is a light to medium brown color. Sapwood can be very wide and tends to be a beige or light bro wn; not always clearly or sharply demarcated from heartwood. Heartwood is rated as perishable, or only slightly durable in regard to decay. Ash is also not resistant to insect attack. Common uses flooring, millwork, boxes/crates, baseball bats, and other turned objects such as tool handles. White Ash has excellent shock resistance, and along with hickory, it is one of the most commonly used hardwoods for tool handles in North America—particularly in shovels and hammers where toughness and impact resistance is important. The emerald ash borer, believed to have been inadvertently introduced from Asia sometime in the 1990s, was first detected in Michigan in 2002. Lacking natural predators, uncontrolled populations

of this invasive species spread very rapidly throughout North America, devastating local populations of ash trees.

wn; not always clearly or sharply demarcated from heartwood. Heartwood is rated as perishable, or only slightly durable in regard to decay. Ash is also not resistant to insect attack. Common uses flooring, millwork, boxes/crates, baseball bats, and other turned objects such as tool handles. White Ash has excellent shock resistance, and along with hickory, it is one of the most commonly used hardwoods for tool handles in North America—particularly in shovels and hammers where toughness and impact resistance is important. The emerald ash borer, believed to have been inadvertently introduced from Asia sometime in the 1990s, was first detected in Michigan in 2002. Lacking natural predators, uncontrolled populations

of this invasive species spread very rapidly throughout North America, devastating local populations of ash trees.

Workability - Produces good results with hand or machine tools. Responds well to steam bending. Glues, stains, and finishes well.

Finishing – oil-based varnishes.

Pricing +

Basswood – From eastern North America. Pale white to light brown color, with sapwood and heartwood sections not clearly defined. Growth rings tend to be subtle, and color is mostly uniform throughout the face grain of the wood. Knots and other defects are uncommon. Basswood is rated as being non-durable in regard to heartwood decay. Common uses carvings, lumber, musical instruments (electric guitar bodies), veneer, plywood, and wood pulp and fiber products. Basswood is an ideal wood for many woodcarvers. Its soft, fine, even texture make it easy to work with, while its pale, inconspicuous color doesn't detract from the carved patterns of the finished product (which also makes it easier to paint and color).

subtle, and color is mostly uniform throughout the face grain of the wood. Knots and other defects are uncommon. Basswood is rated as being non-durable in regard to heartwood decay. Common uses carvings, lumber, musical instruments (electric guitar bodies), veneer, plywood, and wood pulp and fiber products. Basswood is an ideal wood for many woodcarvers. Its soft, fine, even texture make it easy to work with, while its pale, inconspicuous color doesn't detract from the carved patterns of the finished product (which also makes it easier to paint and color).

Though Basswood has high initial shrinkage, the wood is stable in service after it has been dried. And though the wood is both lightweight and soft, it has an outstanding MOE-to-weight ratio. However, its MOR is on par with its low weight; simply put, when put under stress, the wood will remain stiff, but will still break (rupture) at a relatively average weight.

Workability: Easy to work, being very soft and light. Perhaps one of the most suitable wood species for hand carving. Basswood also glues and finishes well, but has poor steam bending and nail holding characteristics.

Finishing – oil-based varnishes

Pricing +

Birch, White - Heartwood tends to be a light reddish brown, with nearly white sapwood. Occasionally figured pieces are available with a wide, shallow curl s imilar to the curl found in Cherry. There is virtually no color distinction between annual growth rings, giving Birch a somewhat dull, uniform appearance. Birch is one of the most widely used woods for veneer and plywood worldwide. Besides regular sheets of plywood, Birch veneer is also used for doors, furniture, and paneling. Plywood, boxes, crates, turned objects, interior trim, and other small specialty wood items. Birch is perishable, and will readily rot and decay if exposed to the elements. The wood is also susceptible to insect attack.

imilar to the curl found in Cherry. There is virtually no color distinction between annual growth rings, giving Birch a somewhat dull, uniform appearance. Birch is one of the most widely used woods for veneer and plywood worldwide. Besides regular sheets of plywood, Birch veneer is also used for doors, furniture, and paneling. Plywood, boxes, crates, turned objects, interior trim, and other small specialty wood items. Birch is perishable, and will readily rot and decay if exposed to the elements. The wood is also susceptible to insect attack.

Workability - Generally easy to work with hand and machine tools, though boards with wild grain can cause grain tearout during machining

operations. Turns, glues, and finishes well.

Finishing – oil-based varnishes

Pricing +

Bloodwood (Satine) – From tropical South America. Traditionally known by the name Satine, it's no wonder that the wood (now more commonly called B loodwood) has grown so popular as an imported wood species. Though it poses some challenges in working characteristics, its hardness, strength, and coloration make this a crimson favorite. Heartwood is a bright, vivid red. Color can darken to a darker brownish red over time with exposure to light. Commonly used for carvings, trim, inlays, furniture, guitars, knife handles, and turned objects.

loodwood) has grown so popular as an imported wood species. Though it poses some challenges in working characteristics, its hardness, strength, and coloration make this a crimson favorite. Heartwood is a bright, vivid red. Color can darken to a darker brownish red over time with exposure to light. Commonly used for carvings, trim, inlays, furniture, guitars, knife handles, and turned objects.

Workability - Bloodwood is extremely dense, and has a pronounced blunting effect on cutters. The wood tends to be brittle and can splinter easily while being worked. Those persistent enough to bear with the difficulties of working with Bloodwood to the finishing stage are rewarded with an exceptional and lustrous red surface.

Finishing – Oil varnish finish works well.

Pricing +++

Bocote – From Mexico and Central/South America. The wood has a yellowish-brown body with dramatic dark brown to almost black stripes. Color tends to  darken with age. The grain patterning can be quite striking. It's not uncommon to see many “eyes” and other figuring: though unlike knots, they do not seem to present any special challenges in machining. It is commonly used for fine furniture, cabinetry, flooring, veneer, boatbuilding, musical instruments, gunstocks, turned objects, and other small specialty wood items. With its striking, zebra-like contrasts, and bold figuring, Bocote can be a very eye-catching wood. Bookmatching two consecutive panels can create symmetrical “faces” and other patterns in the wood, (though a relatively thin-kerf blade should be used to minimize the shift of the pattern). Bocote is generally used for its aesthetic attributes, rather than its mechanical ones—and although Bocote is by no means weak, its strength-to-weight ratio is below average. (It is roughly as stiff and strong as Hard Maple, even though Bocote is considerably heavier.) Bocote can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

darken with age. The grain patterning can be quite striking. It's not uncommon to see many “eyes” and other figuring: though unlike knots, they do not seem to present any special challenges in machining. It is commonly used for fine furniture, cabinetry, flooring, veneer, boatbuilding, musical instruments, gunstocks, turned objects, and other small specialty wood items. With its striking, zebra-like contrasts, and bold figuring, Bocote can be a very eye-catching wood. Bookmatching two consecutive panels can create symmetrical “faces” and other patterns in the wood, (though a relatively thin-kerf blade should be used to minimize the shift of the pattern). Bocote is generally used for its aesthetic attributes, rather than its mechanical ones—and although Bocote is by no means weak, its strength-to-weight ratio is below average. (It is roughly as stiff and strong as Hard Maple, even though Bocote is considerably heavier.) Bocote can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

Workability - Some species may contain silica that will dull cutters. On the whole, Bocote is easily worked and machined with good results. Although Bocote has a fairly high amount of natural oils present, gluing is usually problem-free. Bocote also turns and finishes well.

Finishing – Can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX). Suggest hand-rubbed poly

Pricing - +++++

Bubinga – From Equatorial Africa. Heartwood ranges from a pinkish red to a darker reddish brown with darker purple or black streaks. Bubinga is very frequ ently seen with a variety of figure, including: pommele, flamed, waterfall, quilted, mottled, etc. An immensely popular imported African hardwood, Bubinga may be loved as much for its quirky name as it is for its strength and beauty. Also sometimes called Kevazingo, usually in reference to its decorative rotary-cut veneer. Bubinga has a close resemblance to rosewood, and is often use in place of more expensive woods. Bubinga also has an exceptional strength-to-weight ratio. Commonly used in veneer, inlays, fine furniture, cabinetry, turnings, and other specialty items. Since Bubinga trees can grow so large, natural-edge slabs of the wood have also been used in tabletops and other specialized projects.

ently seen with a variety of figure, including: pommele, flamed, waterfall, quilted, mottled, etc. An immensely popular imported African hardwood, Bubinga may be loved as much for its quirky name as it is for its strength and beauty. Also sometimes called Kevazingo, usually in reference to its decorative rotary-cut veneer. Bubinga has a close resemblance to rosewood, and is often use in place of more expensive woods. Bubinga also has an exceptional strength-to-weight ratio. Commonly used in veneer, inlays, fine furniture, cabinetry, turnings, and other specialty items. Since Bubinga trees can grow so large, natural-edge slabs of the wood have also been used in tabletops and other specialized projects.

Workability - Easy to work overall, though depending upon the species Bubinga can have silica present, which can prematurely dull cutting edges. Also, on pieces with figured or interlocking grain, tearout can occur during planing or other machining operations. Gluing can occasionally be problematic due to Bubinga's high density and natural oils. Turns and finishes well.

Finishing – oil-based varnishes, hand-rubbed poly

Pricing +++

Canarywood – From South America (Panama down to southern Brazil). Wood is yellow to orange in color, typically variegated with light to dark red streakin g. It has a medium to high luster. It can be somewhat variable in density; it is mostly a hard, heavy and strong wood. Works very easily with both hand and power tools and finishes very smoothly. With its beautiful grain and stability, Canarywood is used largely for fine furniture and cabinetry. It is also used for boat parts such as keel, planking and trim plus many other uses such as heavy construction timbers, flooring as well as being sliced for veneers.

g. It has a medium to high luster. It can be somewhat variable in density; it is mostly a hard, heavy and strong wood. Works very easily with both hand and power tools and finishes very smoothly. With its beautiful grain and stability, Canarywood is used largely for fine furniture and cabinetry. It is also used for boat parts such as keel, planking and trim plus many other uses such as heavy construction timbers, flooring as well as being sliced for veneers.

Workability - Easy to work with both hand and machine tools, though some tearout can occur during planing on pieces with wild or irregular grain. Good dimensional stability. Turns, glues and finishes well.

Finishing – oil-based varnishes

Pricing +++

Cedar, Red Aromatic – From Eastern North America. Heartwood tends to be a reddish or violet-brown. Aromatic Red Cedar has a distinct and tell-tale sce nt: the wood is commonly used in closets and chests to repel moths and other insects. Regarded as excellent in resistance to both decay and insect attack, Aromatic Red Cedar is frequently used for fence posts used in direct ground contact with no pre-treating of the wood.

nt: the wood is commonly used in closets and chests to repel moths and other insects. Regarded as excellent in resistance to both decay and insect attack, Aromatic Red Cedar is frequently used for fence posts used in direct ground contact with no pre-treating of the wood.

Workability - Overall, Aromatic Red Cedar is easy to work, notwithstanding any knots or irregularities present in the wood. It reportedly has a high silica content, which can dull cutters. Aromatic Red Cedar glues and finishes well, though in many applications, the wood is left unfinished to preserve its aromatic properties.

Finishing – oil-based varnishes

Pricing - +

Cedar (Spanish) - Native to Central and South America and the Caribbean. Heartwood is a relatively uniform light pinkish to reddish brown; colors tend to d arken with age. Random pockets of gum and natural oils are commonly present. Grain patterning and figure tends to be somewhat bland. A historically valuable Latin-American timber, Spanish Cedar has been exploited in many regions, and the species is now considered to be vulnerable according to the IUCN. Brazil, Bolivia, Columbia, Guatemala, and Peru have voluntarily chosen to control the exporting of the wood, and have sought the cooperation of other countries to help in enforcing these restrictions. Spanish Cedar may still be freely exported from Latin American countries not listed in Appendix III.

arken with age. Random pockets of gum and natural oils are commonly present. Grain patterning and figure tends to be somewhat bland. A historically valuable Latin-American timber, Spanish Cedar has been exploited in many regions, and the species is now considered to be vulnerable according to the IUCN. Brazil, Bolivia, Columbia, Guatemala, and Peru have voluntarily chosen to control the exporting of the wood, and have sought the cooperation of other countries to help in enforcing these restrictions. Spanish Cedar may still be freely exported from Latin American countries not listed in Appendix III.

Not a true cedar, Spanish Cedar is actually more closely related to true Mahoganies, as both are in the Meliaceae family. Density and mechanical properties can vary widely depending on country of origin and growing conditions; (specific gravity can vary from .30 to as high as .60 in some instances). Some of the wood available at present comes from plantations: where younger, faster-growing trees, produce wood that is lower in density, and paler in color than wood cut from trees taken from forests in the wild.

Finishing – none required

Pricing ++

Cherry, Black – From Eastern North America. Heartwood is a light pinkish brown when freshly cut, darkening to a medium reddish brown with time and upo n exposure to light and this quality is considered both desirable and beautiful. Cherry trees produce one of the most desirable woods used to make furniture, cabinetry, fine furniture, flooring, interior millwork, veneer, turned objects, and small specialty wood items.

n exposure to light and this quality is considered both desirable and beautiful. Cherry trees produce one of the most desirable woods used to make furniture, cabinetry, fine furniture, flooring, interior millwork, veneer, turned objects, and small specialty wood items.

(Cherry, Gummy -

Gum spots or small dark longitudinal liaisons about 1/16 inches wide to ½ inch, or longer, are a common characteristics of cherry. Dark streaks which extend for several inches can be associated with the gum spots. Gum spots can be larger, and sometimes gum even follows an entire growth ring around the tree. These spots are caused by wounding or by a peach bark borer, which feeds on the tree cambium. The cambium responds by forming the gum spot. When a finish is applied, it may not be able to bridge gum spots and thus the product may appear defective.)

Workability - Cherry is known as being one of the best all-around woods for workability. It is stable, straight-grained, and machines well. The only difficulties typically arise if the wood is being stained, as it can sometimes give blotchy results—using a sanding sealer prior to staining, or using a

gel-based stain is recommended. Sapwood is common, and may contribute to a high wastage factor.

Finishing – oil-based varnishes

Pricing +

Cherry, Brazilian (see Jatoba)

Cocobolo (Granadillo) - Cocobolo is a tropical hardwood from Central America. Only the heartwood is used: this is typically orange or reddish-brown in col or, often with a figuring of darker irregular traces weaving through the wood. Cocobolo is oily in look and feel. This oil lends a strong, unmistakable floral odor even to well-seasoned wood and occasionally stains the hands with prolonged exposure. Standing up well to repeated handling and exposure to water, a common use is in gun grips and knife handles. Besides its use in gun grips and knife handles, cocobolo is favored for fine inlay work for custom high-end cue sticks, police batons, pens, brush backs, and musical instruments, especially guitars, drums and basses. It is very hard, fine textured, and dense, but is easily machined, although due to the abundance of natural oils, the wood tends to clog abrasives and fine-toothed saw blades, like other very hard, very dense tropical woods. Due to its density and hardness a board will not float, and even a large block of the cut wood will produce a clear musical tone if struck. Cocobolo can be polished to a lustrous, glassy finish. Cocobolo can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

or, often with a figuring of darker irregular traces weaving through the wood. Cocobolo is oily in look and feel. This oil lends a strong, unmistakable floral odor even to well-seasoned wood and occasionally stains the hands with prolonged exposure. Standing up well to repeated handling and exposure to water, a common use is in gun grips and knife handles. Besides its use in gun grips and knife handles, cocobolo is favored for fine inlay work for custom high-end cue sticks, police batons, pens, brush backs, and musical instruments, especially guitars, drums and basses. It is very hard, fine textured, and dense, but is easily machined, although due to the abundance of natural oils, the wood tends to clog abrasives and fine-toothed saw blades, like other very hard, very dense tropical woods. Due to its density and hardness a board will not float, and even a large block of the cut wood will produce a clear musical tone if struck. Cocobolo can be polished to a lustrous, glassy finish. Cocobolo can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

Workability: Due to the high oil content found in this wood, it can occasionally cause problems with gluing. Also, the wood's color can bleed into surrounding wood when applying a finish, so care must be taken on the initial seal coats not to smear the wood's color/oils into surrounding areas. Tearout can occur during planing if interlocked grain is present; the wood also has a moderate blunting effect on cutting edges/tools due to its high density. Cocobolo has excellent turning properties.

Finishing – best to use dewaxed shellac, try hand-rubbed poly

Pricing +++

Ebiara (Berlinia, Poculi, Red Zebrawood) - From equatorial West Africa in Cameroon, Gabon, Sierra Leone, Ivory Coast, Congo and Zaire. It is commonly ca lled Mposso in West Africa. The wood that is produced from this tree looks like a hybrid cross of Zebra wood and Bubinga. It has the beautiful reds of Bubinga with the striking stripes of Zebra in one species. Ebiara has traumatic resin canals, which are seen as the black stripes in the length direction. It is mainly used in boxes, cabinets , stairs, parquet flooring, moldings, furniture, paneling, picture frames, turned articles, and to make musical instruments.

lled Mposso in West Africa. The wood that is produced from this tree looks like a hybrid cross of Zebra wood and Bubinga. It has the beautiful reds of Bubinga with the striking stripes of Zebra in one species. Ebiara has traumatic resin canals, which are seen as the black stripes in the length direction. It is mainly used in boxes, cabinets , stairs, parquet flooring, moldings, furniture, paneling, picture frames, turned articles, and to make musical instruments.

Workability - Generally easy to work with hand or machine tools, though planing or surfacing interlocked grain may result in tearout, particularly on quartersawn surfaces. Glues, turns, and finishes well.

Finishing – oil-based varnishes

Pricing +++

Goncalo Alves (Tigerwood) - Obtained from Mexico southward to Brazil. It is sometimes referred to as zebrawood or tigerwood - names that underscore th e wood's often dramatic, contrasting color scheme. Heartwood is typically a medium reddish brown with irregularly spaced streaks of dark brown to black. Color tends to darken with age. Goncalo Alves is used in making high-value items such as archery bows, billiard-cue butts, jewelry boxes, and turnings. In veneer form, it becomes panels and decorative accents on fine furniture. The wood has superb stiffness, strength, hardness, and durability. However, density and other mechanical properties can vary widely depending on the growing site and source region. The name “Jobillo” is sometimes used to refer to higher grades of Goncalo Alves among woodturners.

e wood's often dramatic, contrasting color scheme. Heartwood is typically a medium reddish brown with irregularly spaced streaks of dark brown to black. Color tends to darken with age. Goncalo Alves is used in making high-value items such as archery bows, billiard-cue butts, jewelry boxes, and turnings. In veneer form, it becomes panels and decorative accents on fine furniture. The wood has superb stiffness, strength, hardness, and durability. However, density and other mechanical properties can vary widely depending on the growing site and source region. The name “Jobillo” is sometimes used to refer to higher grades of Goncalo Alves among woodturners.

Workability - Goncalo Alves is generally not too difficult to work, despite its high density. Figured pieces with irregular grain can pose a challenge in planing and machining operations. Goncalo Alves can also have a moderate blunting effect on cutters. The wood is very resistant to moisture absorption, which can make it difficult to glue. Goncalo Alves turns and finishes well.

Finishing – In gluing goncalo alves, first wipe the wood in the joints with a solvent to clear natural extractives. Then, because its density resists glue absorption, use an adhesive with a longer open time, such as woodworker's white glue. Put on a light coat, briefly join the pieces, then pull them apart and let the glue set up a bit before reassembling the wood.

Pricing ++

Hickory – From Eastern United States. Heartwood tends to be light to medium brown, with a reddish hue; sapwood is a paler yellowish brown. Boards with co ntrasting heartwood and sapwood create a somewhat rustic appearance that's sometimes marketed as Calico Hickory. Hickory is among the hardest and strongest of woods native to the United States. On average, Hickory is denser, stiffer, and harder than either White Oak or Hard Maple. The wood is commonly used where strength or shock-resistance is important. Shellbark Hickory falls into the True-Hickory grouping, and is considered to be a ring-porous wood. The strength

ntrasting heartwood and sapwood create a somewhat rustic appearance that's sometimes marketed as Calico Hickory. Hickory is among the hardest and strongest of woods native to the United States. On average, Hickory is denser, stiffer, and harder than either White Oak or Hard Maple. The wood is commonly used where strength or shock-resistance is important. Shellbark Hickory falls into the True-Hickory grouping, and is considered to be a ring-porous wood. The strength

characteristics of Hickory are influenced considerably by the spacing of its growth rings. In general, wood from faster-growing trees, with wider spaced growth rings, tends to be harder, heavier, and stronger than wood from slower-growing trees that have rings which are closer together. In addition to strength and hardness applications, the wood of Carya species also has a very high thermal energy content when burned, and is sometimes used as fuelwood for wood stoves. Additionally, Hickory is also used as charcoal in cooking meat, with the smoke imparting additional flavor to the food.

Workability - Difficult to work, with tearout being common during machining operations if cutting edges are not kept sharp; the wood tends to blunt cutting edges. Glues, stains, and finishes well. Responds well to steam bending.

Finishing – oil-based varnishes

Pricing +

Ipe (Brazilian Walnut) – Ipe is a wood of extremes: extremely dense and durable, as well as extremely difficult to work. Its incredible hardness and strength make it well suited for flooring applications, though it is referred to as “Brazilian Walnut” among flooring dealers—though it is not related to true Walnut in the Juglans genus. It is three times harder than oak, and a board will sink in water. The heartwood of Ipe has a color that ranges from reddish brown to blackish brown to yellowish olive brown. It is normal to see the wood having black and brown stripes. The Ipe wood has fine to medium texture. It features straight to their regular pattern of the grain. It is commonly used for flooring, decking, exterior lumber, veneer, tool handles, and other turned objects. It is very durable and has excellent insect resistance.

make it well suited for flooring applications, though it is referred to as “Brazilian Walnut” among flooring dealers—though it is not related to true Walnut in the Juglans genus. It is three times harder than oak, and a board will sink in water. The heartwood of Ipe has a color that ranges from reddish brown to blackish brown to yellowish olive brown. It is normal to see the wood having black and brown stripes. The Ipe wood has fine to medium texture. It features straight to their regular pattern of the grain. It is commonly used for flooring, decking, exterior lumber, veneer, tool handles, and other turned objects. It is very durable and has excellent insect resistance.

Workability - Overall, Ipe is a difficult wood to work, being extremely hard and dense, with high cutting resistance during sawing. Ipe also has a pronounced blunting effect on cutting edges. The wood generally planes smoothly, but the grain can tearout on interlocked areas. Also, Ipe can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

Finish - Besides being hard, ipe is an oily wood, and any type of finish that forms a film, such as varnish or polyurethane, will begin to peel and flake soon after you apply it. A better option is to use a penetrating oil finish. The oil won't penetrate the close-grained wood very deeply, however, and the residue that remains on the surface will quickly become tacky unless you wipe it off. Consequently, the best way to finish ipe is to brush on a light coat of oil with a paintbrush and wipe off the excess almost immediately. The best covering is a thin coat of ultraviolet-blocking oil- or water-based penetrating finish.

Pricing +++

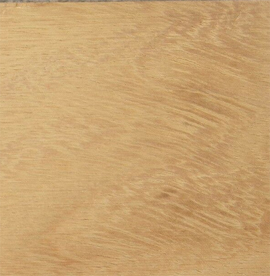

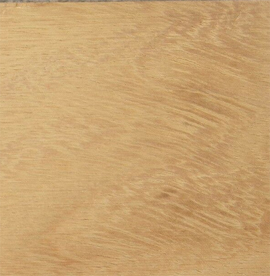

Iroko – From Tropical Africa. Heartwood is usually a yellow to golden or medium brown, with color tending to darken over time. Given the high prices of gen uine Teak, Iroko could be considered a low-cost alternative. The wood is stable, durable, and has an overall look that somewhat resembles Teak. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

uine Teak, Iroko could be considered a low-cost alternative. The wood is stable, durable, and has an overall look that somewhat resembles Teak. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation.

Workability - Generally easy to work, with the exception of its interlocked grain, which may cause some tearout during surfacing operations. Also, deposits of calcium carbonate are sometimes present, which can have a significant dulling effect on cutters. Iroko glues and finishes well.

Finishing – oil-based varnishes

Pricing ++

Jatoba (Brazilian Cherry) – From Central America, southern Mexico, northern South America, and the West Indies. Heartwood varies from a light orangis h brown to a darker reddish brown, sometimes with contrasting darker grayish brown streaks. Color tends darken upon exposure to light. Commonly used for flooring, furniture, cabinetry, tool handles, shipbuilding, railroad ties, turned objects, and other small specialty items. Jatoba is exceptionally stiff, strong, and hard.

h brown to a darker reddish brown, sometimes with contrasting darker grayish brown streaks. Color tends darken upon exposure to light. Commonly used for flooring, furniture, cabinetry, tool handles, shipbuilding, railroad ties, turned objects, and other small specialty items. Jatoba is exceptionally stiff, strong, and hard.

Workability - Jatoba is considered difficult to work with on account of its density and hardness, and has a moderate blunting effect on tool cutters. Jatoba also tends to be difficult to plane without tearout due to its interlocking grain. However, Jatoba glues, stains, turns, and finishes well. Responds well to steam-bending.

Finishing – oil-based varnishes

Pricing ++

Lacewood – From Tropical South America. Has a very conspicuous flecking that gives this wood its namesake. The wood itself is a reddish brown with grey  or light brown rays, which result in a lace pattern when quartersawn. Like other woods that exhibit the strongest figure in quartersawn pieces, (such as Sycamore), Lacewood has the most pronounced figure and displays the largest flecks when perfectly quartersawn; this is due to the wood's wide medullary rays, whose layout can be seen the clearest when looking at the endgrain. The name “Lacewood” is used very loosely and can be applied (and misapplied) to a number of different wood species. Leopardwood looks similar, but tends to be slightly darker brown, and is significantly heavier.

or light brown rays, which result in a lace pattern when quartersawn. Like other woods that exhibit the strongest figure in quartersawn pieces, (such as Sycamore), Lacewood has the most pronounced figure and displays the largest flecks when perfectly quartersawn; this is due to the wood's wide medullary rays, whose layout can be seen the clearest when looking at the endgrain. The name “Lacewood” is used very loosely and can be applied (and misapplied) to a number of different wood species. Leopardwood looks similar, but tends to be slightly darker brown, and is significantly heavier.

Workability - Overall a fairly easy wood to work with, taking glues, stains, and finishes well; though there may be some difficulty in planing, with tearout occurring. Some species of lacewood can also have a moderate blunting effect on cutting edges.

Finishing – oil-based varnishes

Pricing +++

Leopardwood – Leopardwood is from trees that are native to Australia and Brazil. It is becoming difficult to obtain Australia Leopard Wood. The origins of both the Australian and Brazilian species were a single proto-species - possibly as far back as the times of Pangea. The wood is so named for the tightly-grouped flecks which cover its surface. It is almost exclusively quartersawn, which displays its dramatic flecking in leopard-spot-like patterns (thus, the name). It is medium to dark, reddish brown in color. Prior to being sanded, the flecked portion's slightly elevated positioning on the wood's surface gives it a true 3D look. It is fairly difficult to work and its uneven texture can cause tearout issues when boards are planed. The inherent decorative properties of Leopard Wood lumber make it a prized choice for veneer, cabinet making, furniture, musical instruments), and turned objects.

both the Australian and Brazilian species were a single proto-species - possibly as far back as the times of Pangea. The wood is so named for the tightly-grouped flecks which cover its surface. It is almost exclusively quartersawn, which displays its dramatic flecking in leopard-spot-like patterns (thus, the name). It is medium to dark, reddish brown in color. Prior to being sanded, the flecked portion's slightly elevated positioning on the wood's surface gives it a true 3D look. It is fairly difficult to work and its uneven texture can cause tearout issues when boards are planed. The inherent decorative properties of Leopard Wood lumber make it a prized choice for veneer, cabinet making, furniture, musical instruments), and turned objects.

Workability – Fairly difficult to work because of its high density and tendency to tearout during planing. Leopardwood glues and finishes well.

Finishing – oil-based varnishes

Pricing +++++

Mahogany, African – From west Tropical Africa. Heartwood color is variable, ranging from a very pale pink to a deeper reddish brown, sometimes with  streaks of medium to dark reddish brown. Color tends to darken with age. Quartersawn surfaces can also exhibit a ribbon-stripe appearance. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses veneer, plywood, turned items, furniture, boatbuilding, and interior trim. Considered to be a valid substitute for Honduran, otherwise known as “Genuine Mahogany.”

streaks of medium to dark reddish brown. Color tends to darken with age. Quartersawn surfaces can also exhibit a ribbon-stripe appearance. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses veneer, plywood, turned items, furniture, boatbuilding, and interior trim. Considered to be a valid substitute for Honduran, otherwise known as “Genuine Mahogany.”

Workability - Easy to work, glue, and finish. Tearout can sometimes be a problem if the grain is interlocked.

Finishing – oil-based varnishes.

Pricing +++

Mahogany, Honduran – Found f rom Southern Mexico to central South America; also commonly grown on plantations. Heartwood color can vary a fair a mount with Honduran Mahogany, from a pale pinkish brown, to a darker reddish brown. Color tends to darken with age. Mahogany also exhibits an optical phenomenon known as chatoyancy (colors change as the piece rotates). This wood species is in CITES Appendix II, and is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses furniture, cabinetry, turned objects, veneers, musical instruments, boatbuilding, and carving. An incredibly important commercial timber in Latin America, Honduran Mahogany is now grown extensively on plantations. It has been widely exploited, leading to its inclusion on the CITES Appendix II in 2003. In effect, this limits the international exporting of the lumber to certified sustainable sources. (This is also why many lumber retailers located in the United States are unable to ship Honduran Mahogany outside of the country.) Substitutes sometimes used are African Mahogany or Sapele.

mount with Honduran Mahogany, from a pale pinkish brown, to a darker reddish brown. Color tends to darken with age. Mahogany also exhibits an optical phenomenon known as chatoyancy (colors change as the piece rotates). This wood species is in CITES Appendix II, and is on the IUCN Red List. It is listed as vulnerable due to a population reduction of over 20% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses furniture, cabinetry, turned objects, veneers, musical instruments, boatbuilding, and carving. An incredibly important commercial timber in Latin America, Honduran Mahogany is now grown extensively on plantations. It has been widely exploited, leading to its inclusion on the CITES Appendix II in 2003. In effect, this limits the international exporting of the lumber to certified sustainable sources. (This is also why many lumber retailers located in the United States are unable to ship Honduran Mahogany outside of the country.) Substitutes sometimes used are African Mahogany or Sapele.

Workability - Typically very easy to work with tools: machines well. (With exception to sections with figured grain, which can tearout or chip during machining.) Slight dulling of cutters can occur. Sands very easily. Turns, glues, stains, and finishes well.

Finishing – oil-based varnishes.

Pricing ++

Makore – From Western and Middle Africa. Heartwood pink or reddish brown, sometimes with streaks of mild color variation. Yellowish sapwood can be tw o to three inches wide, and is clearly demarcated from the heartwood. Figured grain patterns (such as mottled or curly) are a common occurrence. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses include veneer, plywood, furniture, cabinetry, flooring, boatbuilding, musical instruments, turned objects, and other small wooden specialty items. Makore is sometimes used in place of African Mhaogany, and has been sold under the trade name Cherry Mahogany

o to three inches wide, and is clearly demarcated from the heartwood. Figured grain patterns (such as mottled or curly) are a common occurrence. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline in its natural range, and exploitation. Common uses include veneer, plywood, furniture, cabinetry, flooring, boatbuilding, musical instruments, turned objects, and other small wooden specialty items. Makore is sometimes used in place of African Mhaogany, and has been sold under the trade name Cherry Mahogany

Workability - Generally easy to work, though sections with interlocked grain can cause tearout during planing or other machining operations. Makore will react when put into direct contact with iron, becoming discolored and stained. Makore also has a pronounced blunting effect on cutters due to its high silica content. Besides this dulling effect, Makore turns well, and is easy to glue and finish.

Finishing – oil-based varnishes

Pricing +

Maple Ambrosia – Found primarily in temperate regions in the Northern Hemisphere. The majority of ambrosia maple is found in species of soft maple. T he ambrosia character in the maple wood is caused by a beetle which bores through the living wood, carrying a fungus on its legs/carapace that is deposited on the wood fibers. As the sap continues to flow through the tree, it causes the fungus to spread out through the wood from the small holes carved by the beetle. This ambrosia fungus, which gives the wood its name, causes discoloration in the maple lumber ranging through various shades of brown, but sometimes including orange, pink, green, and light purple. When boards are flat-sawn from these logs, the ambrosia signature is accentuated, and the wood achieves a highly unique appearance with a distinctly rustic nature. Although created by this combination of beetle and fungus activity, ambrosia maple is sometimes referred to as "wormy" maple.

he ambrosia character in the maple wood is caused by a beetle which bores through the living wood, carrying a fungus on its legs/carapace that is deposited on the wood fibers. As the sap continues to flow through the tree, it causes the fungus to spread out through the wood from the small holes carved by the beetle. This ambrosia fungus, which gives the wood its name, causes discoloration in the maple lumber ranging through various shades of brown, but sometimes including orange, pink, green, and light purple. When boards are flat-sawn from these logs, the ambrosia signature is accentuated, and the wood achieves a highly unique appearance with a distinctly rustic nature. Although created by this combination of beetle and fungus activity, ambrosia maple is sometimes referred to as "wormy" maple.

Finishing – oil-based varnishes

Pricing ++

Maple Birdseye – From northeastern North America. Birdseye Maple is not technically a distinct species of Maple, but rather, it's a figure that's occasionally found in Sugar Maple trees. It's named “birdseye” (sometimes simply written out as: Bird's Eye Maple ) because the figure resembles small bird's eyes. The figure is reportedly caused by unfavorable growing conditions for the tree. The tree attempts to start numerous new buds to get more sunlight, but with poor growing conditions the new shoots are aborted, and afterward a number of tiny knots remain. Research into the cultivation of bird's eye maple has so far discounted the theories that it is caused by pecking birds deforming the wood grain or that an infecting fungus makes it twist. However, no one has demonstrated a complete understanding of any combination of climate, soil, tree variety, insects, viruses or genetic mutation that may produce the effect. Although there are a few clues in a tree's bark that indicate the lumber might have bird's eye figure, it is usually necessary to fell the tree and cut it apart to know for sure.

found in Sugar Maple trees. It's named “birdseye” (sometimes simply written out as: Bird's Eye Maple ) because the figure resembles small bird's eyes. The figure is reportedly caused by unfavorable growing conditions for the tree. The tree attempts to start numerous new buds to get more sunlight, but with poor growing conditions the new shoots are aborted, and afterward a number of tiny knots remain. Research into the cultivation of bird's eye maple has so far discounted the theories that it is caused by pecking birds deforming the wood grain or that an infecting fungus makes it twist. However, no one has demonstrated a complete understanding of any combination of climate, soil, tree variety, insects, viruses or genetic mutation that may produce the effect. Although there are a few clues in a tree's bark that indicate the lumber might have bird's eye figure, it is usually necessary to fell the tree and cut it apart to know for sure.

Finishing – oil-based varnishes

Pricing +++

Maple Flame (Curly Maple, Tiger Maple, Fiddleback Maple, Rippled Maple) – Found in temperate regions in the Northern Hemisphere. The feature of maple in which the growth of the wood fibers is distorted in an undulating chatoyant pattern, producing wavy lines known as "flames". This effect is often mistakenly said to be part of the grain of the wood; it is more accurately called "figure", as the distortion is perpendicular to the grain direction. Prized for its beautiful appearance, it is used frequently in the manufacturing of musical instruments, such as violins and bassoons, and fine furniture. Another well-known use of the material is its use in guitars, especially the venerated Gibson Les Paul. The Gibson Les Paul "Standard", initially manufactured from 1958 to 1960, sported a flame maple top finished in a cherry-red sunburst on a mahogany body. Today, these instruments are some of the most prized on the vintage guitar market, and as such are unaffordable to most musicians.

maple in which the growth of the wood fibers is distorted in an undulating chatoyant pattern, producing wavy lines known as "flames". This effect is often mistakenly said to be part of the grain of the wood; it is more accurately called "figure", as the distortion is perpendicular to the grain direction. Prized for its beautiful appearance, it is used frequently in the manufacturing of musical instruments, such as violins and bassoons, and fine furniture. Another well-known use of the material is its use in guitars, especially the venerated Gibson Les Paul. The Gibson Les Paul "Standard", initially manufactured from 1958 to 1960, sported a flame maple top finished in a cherry-red sunburst on a mahogany body. Today, these instruments are some of the most prized on the vintage guitar market, and as such are unaffordable to most musicians.

Finishing – oil-based varnishes.

Pricing +

Maple Hard - The Hard Maple Tree is usually referred to as Sugar Maple, and is the tree most often tapped for maple syrup. Sugar Maple's leaves are the s hape that most people associate with maple leaves; they typically have either 5 or 7 lobes, with vivid autumn coloring ranging from yellow to purplish red. Its wood is stronger, stiffer, harder, and denser than all the other species of Maple commercially available in lumber form. (It's also the state tree in four different states in the US.) Unlike most other hardwoods, the sapwood of Hard Maple lumber is most commonly used rather than its heartwood. Sapwood color ranges from nearly white, to an off-white cream color, sometimes with a reddish or golden hue. Hard maple is commonly used for flooring (from basketball courts and dance-floors to bowling alleys and residential), paper (pulpwood), making

of musical instruments, cutting boards, butcher blocks, workbenches, baseball bats, and other turned objects and specialty wood items.

hape that most people associate with maple leaves; they typically have either 5 or 7 lobes, with vivid autumn coloring ranging from yellow to purplish red. Its wood is stronger, stiffer, harder, and denser than all the other species of Maple commercially available in lumber form. (It's also the state tree in four different states in the US.) Unlike most other hardwoods, the sapwood of Hard Maple lumber is most commonly used rather than its heartwood. Sapwood color ranges from nearly white, to an off-white cream color, sometimes with a reddish or golden hue. Hard maple is commonly used for flooring (from basketball courts and dance-floors to bowling alleys and residential), paper (pulpwood), making

of musical instruments, cutting boards, butcher blocks, workbenches, baseball bats, and other turned objects and specialty wood items.

Finishing – oil-based varnishes.

Pricing +

Maple Quilted - Quilted Maple is not actually a species, but simply a description of a figure in the grain. Quilted maple occurs most often in soft maples, b ut is also seen in hard maples. The highest grade quilted maple is most commonly seen in Bigleaf Maple. Quilted maple is so named for its resemblance to patchwork patterns seen on fabric quilts. There are varying grades of quilted maple, based upon the perceived depth of the quilt, as well as the purity of color of the wood itself (with a pure and uniform white being the most valuable). Quilted maple billets are often sold for extremely high prices for use as tops of electric guitars. They are frequently dyed in outlandish colors such as blue, green, or purple to give an “electric” effect to the grain pattern. One technique that is used to further enhance the grain pattern is to initially dye the wood a very dark brown or black, and then sand back almost to raw wood, leaving just a residue of black dye remaining in the low spots of the grain's figure, and then reapply a dye of the final color. The result will be accented and shadowed by the darker dye that was left in the low portions of the grain, while the primary color is brought out in the body of the wood.

ut is also seen in hard maples. The highest grade quilted maple is most commonly seen in Bigleaf Maple. Quilted maple is so named for its resemblance to patchwork patterns seen on fabric quilts. There are varying grades of quilted maple, based upon the perceived depth of the quilt, as well as the purity of color of the wood itself (with a pure and uniform white being the most valuable). Quilted maple billets are often sold for extremely high prices for use as tops of electric guitars. They are frequently dyed in outlandish colors such as blue, green, or purple to give an “electric” effect to the grain pattern. One technique that is used to further enhance the grain pattern is to initially dye the wood a very dark brown or black, and then sand back almost to raw wood, leaving just a residue of black dye remaining in the low spots of the grain's figure, and then reapply a dye of the final color. The result will be accented and shadowed by the darker dye that was left in the low portions of the grain, while the primary color is brought out in the body of the wood.

Finishing – oil-based varnishes.

Pricing ++++

Maple, Soft – From temperate regions North America. Soft (Acer rubrum and Acer saccharinum) is a relative term and is only used to differentiate it from hard maple . For many applications, soft maple's hardness is sufficient, and its reduced density generally means it's easier to work with and machine than hard maple. Unlike most other hardwoods, the sapwood of maple lumber is most commonly used rather than its heartwood. Sapwood color ranges from almost white, to a light golden or reddish brown, while the heartwood is a darker reddish brown. Silver Maple can also be seen with curly or quilted grain patterns.

hard maple . For many applications, soft maple's hardness is sufficient, and its reduced density generally means it's easier to work with and machine than hard maple. Unlike most other hardwoods, the sapwood of maple lumber is most commonly used rather than its heartwood. Sapwood color ranges from almost white, to a light golden or reddish brown, while the heartwood is a darker reddish brown. Silver Maple can also be seen with curly or quilted grain patterns.

Finishing – oil-based varnishes

Pricing +

Movingui (Ayan, Nigerian Satinwood) - From primarily West Africa. Yellow to orangish brown; color tends to darken with age. Movingui frequently ex hibits figured grain patterns such as mottle or ripple. Its yellow color can be quite vibrant, while it can also have highly pronounced mottle figure, making it a favorite for veneering and applications used for accents. Movingui is moderately resistant to termites and dries with very little degrade. It is nearly identical in hardness to yellow birch, ninety-five percent as hard as red oak, roughly eighty-five percent as hard as hard maple, and about two-thirds as hard as either hickory or pecan. Main uses veneer, cabinetry, furniture, and flooring.

hibits figured grain patterns such as mottle or ripple. Its yellow color can be quite vibrant, while it can also have highly pronounced mottle figure, making it a favorite for veneering and applications used for accents. Movingui is moderately resistant to termites and dries with very little degrade. It is nearly identical in hardness to yellow birch, ninety-five percent as hard as red oak, roughly eighty-five percent as hard as hard maple, and about two-thirds as hard as either hickory or pecan. Main uses veneer, cabinetry, furniture, and flooring.

Workability - Generally the wood is easy to work, though Movingui can have up to 1.3% silica content by weight, which may result in blunting effects

ranging from moderate to severe. Quartersawn surfaces may be inclined to tearout during planing, and charring of the wood may occur during drilling. Movingui glues, stains, and finishes well. Responds moderately well to steam bending.

Finishing - oil-based varnishes

Pricing ++

Mozambique (Shedua ) – From Tropical West Africa. This wood wins the award for the most commonly used aliases, with no single name being predomin ant. When used in guitars, it's most commonly referred to as Ovangkol. Most other woodworkers favor either Shedua or Amazique, while veneer is sometimes sold under the name Mozambique. All refer to the same wood species: Guibourtia ehie. Varying shades of yellowish to reddish brown with darker brown, gray, or black stripes. Moderately wide sapwood is a pale yellow, clearly demarcated from heartwood. Sometimes seen with a curly or mottled grain pattern. Common uses include veneer, furniture, cabinetry, turned objects, musical instruments, and flooring.

ant. When used in guitars, it's most commonly referred to as Ovangkol. Most other woodworkers favor either Shedua or Amazique, while veneer is sometimes sold under the name Mozambique. All refer to the same wood species: Guibourtia ehie. Varying shades of yellowish to reddish brown with darker brown, gray, or black stripes. Moderately wide sapwood is a pale yellow, clearly demarcated from heartwood. Sometimes seen with a curly or mottled grain pattern. Common uses include veneer, furniture, cabinetry, turned objects, musical instruments, and flooring.

Workability - Overall a fairly easy wood to work, though contains silica and can therefore dull cutters prematurely. Also, if the grain is interlocked,

or if there is other figure present in the wood, planing and other machining operations may be troublesome and cause tearout. Turns, glues and finishes well.

Finishing – oil-based varnishes

Pricing +++

Oak, Red – From Northeastern United States and Southeastern Canada. Heartwood is a light to medium brown, commonly with a reddish cast. Nearly whit e to light brown sapwood is not always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns. Arguably the most popular hardwood in the United States, Red Oak is a ubiquitous sight in many homes. Even many vinyl/imitation wood surfaces are printed to look like Red Oak. Hard, strong, and moderately priced, Red Oak presents an exceptional value to woodworkers—which explains why it is so widely used in cabinet and furniture making. Common uses cabinetry, furniture, interior trim, flooring, and veneer.

e to light brown sapwood is not always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns. Arguably the most popular hardwood in the United States, Red Oak is a ubiquitous sight in many homes. Even many vinyl/imitation wood surfaces are printed to look like Red Oak. Hard, strong, and moderately priced, Red Oak presents an exceptional value to woodworkers—which explains why it is so widely used in cabinet and furniture making. Common uses cabinetry, furniture, interior trim, flooring, and veneer.

Workability - Produces good results with hand and machine tools. Has moderately high shrinkage values, resulting in mediocre dimensional stability, especially in flatsawn boards. Can react with iron (particularly when wet) and cause staining and discoloration. Responds well to steam-bending. Glues,

stains, and finishes well.

Finishing – oil-based varnishes

Pricing +

Roasted Red Oak - Red Oak lumber is heat-treated in a chemical-free process that uses heat and pressure that makes it weather-resistant and oxidizes the natural color to dark brown. A simple clear oil finish will turn the wood black. From Northeastern United States and Southeastern Canada. Heartwood is a light to medium brown,

to dark brown. A simple clear oil finish will turn the wood black. From Northeastern United States and Southeastern Canada. Heartwood is a light to medium brown,

commonly with a reddish cast. Nearly white to light brown sapwood is not always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns. Arguably the most popular hardwood in the United States, Red Oak is a ubiquitous sight in many homes. Even many vinyl/imitation wood surfaces are printed to look like Red Oak. Hard, strong, and moderately priced, Red Oak presents an exceptional value to woodworkers—which explains why it is so widely used in cabinet and furniture making. Common uses cabinetry, furniture, interior trim, flooring, and

veneer.

Workability - Produces good results with hand and machine tools. Has moderately high shrinkage values, resulting in mediocre dimensional stability, especially in flatsawn boards. Can react with iron (particularly when wet) and cause staining and discoloration. Responds well to steam-bending. Glues, stains, and finishes well.

Finishing – Oils or oil-based varnishes

Pricing ++

Oak, White – From Eastern United States. Heartwood is a light to medium brown, commonly with an olive cast. Nearly white to light brown sapwood is no t always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns. Rated as very durable; frequently used in cabinetry, furniture, interior trim, flooring, boatbuilding, barrels, and veneer.

t always sharply demarcated from the heartwood. Quartersawn sections display prominent ray fleck patterns. Rated as very durable; frequently used in cabinetry, furniture, interior trim, flooring, boatbuilding, barrels, and veneer.

Workability - Produces good results with hand and machine tools. Has moderately high shrinkage values, resulting in mediocre dimensional stability, especially in flatsawn boards. Can react with iron (particularly when wet) and cause staining and discoloration. Responds well to steam-bending. Glues, stains, and finishes well.

Finishing – oil-based varnishes

Pricing +

Olivewood -

Heartwood is a cream or yellowish brown, with darker brown or black contrasting streaks. Color tends to deepen with age. Olive is somtimes figured with curly or wavy grain, burl, or wild grain.

Conflicting reports range from non-durable/perishable to durable/moderately durable. Olive is susceptible to insect attack. Used for high-end f urniture, veneer, turned objects, and small specialty wood items.

urniture, veneer, turned objects, and small specialty wood items.

Workability - Somewhat easy to work, though wild or interlocked grain may result in tearout during surfacing operations. Olive has high movement in service and is considered to have poor stability. Turns superbly. Glues and finishes well.

Because of the fruit's economic importance, healthy, cultivated Olive trees (O. europaea) aren't felled for lumber; availability is generally limited to pruned branches, trimmings, and diseased/storm damaged orchard trees. Short lumber, turning squares, and burls are occasionally available from wild trees, as well as the closely related East African Olive (O. capensis) .

Finishing – oil-based varnishes

Pricing +++

Padauk, African – From Central and tropical west Africa. Heartwood color can vary, ranging from a pale pinkish orange to a deep brownish red. Most piec es tend to start reddish orange when freshly cut, darkening substantially over time to a reddish/purplish brown (some lighter pieces age to a grayish brown). Has excellent decay resistance, and is rated as durable to very durable. Padauk is also reported to be resistant to termites and other insects. Common uses are veneer, flooring, turned objects, musical instruments, furniture, tool handles, and other small specialty wood objects. Padauk has a very unique reddish orange coloration, and the wood is sometimes referred to by the name Vermillion. Unfortunately, this dramatic color is inevitably darkened to a deep reddish-brown color. Padauk is moderately heavy, strong, and stiff, with exceptional stability. It's a popular hardwood among hobbyist woodworkers because of its unique color and low cost.

es tend to start reddish orange when freshly cut, darkening substantially over time to a reddish/purplish brown (some lighter pieces age to a grayish brown). Has excellent decay resistance, and is rated as durable to very durable. Padauk is also reported to be resistant to termites and other insects. Common uses are veneer, flooring, turned objects, musical instruments, furniture, tool handles, and other small specialty wood objects. Padauk has a very unique reddish orange coloration, and the wood is sometimes referred to by the name Vermillion. Unfortunately, this dramatic color is inevitably darkened to a deep reddish-brown color. Padauk is moderately heavy, strong, and stiff, with exceptional stability. It's a popular hardwood among hobbyist woodworkers because of its unique color and low cost.

Workability - Overall Padauk is easy to work; tearout may also occur during planing on quartersawn or interlocked grain. Padauk turns, glues, and finishes well

Finishing – oil-based varnishes. UV-inhibiting finishes may prolong, but not prevent the gradual color-shift of this brightly colored wood.

Pricing +++

Purpleheart – From Central and South America (from Mexico down to southern Brazil).

Grain is usually straight often with a fine curly figure. Fine texture. Moderately hard to work but takes a glossy, lustrous finish. Lacquer finish w ill best preserve the color. Sometimes called Amaranth, this colorful Latin American hardwood is tremendously popular for furniture and other designs that call for a unique splash of color. It is used in Inlays/accent pieces, flooring, furniture, boatbuilding, heavy construction, and a variety of specialty wood items. In addition to its coloration, Purpleheart has excellent strength properties, and can be used in applications where strength is important—a wood for both form and function.

ill best preserve the color. Sometimes called Amaranth, this colorful Latin American hardwood is tremendously popular for furniture and other designs that call for a unique splash of color. It is used in Inlays/accent pieces, flooring, furniture, boatbuilding, heavy construction, and a variety of specialty wood items. In addition to its coloration, Purpleheart has excellent strength properties, and can be used in applications where strength is important—a wood for both form and function.

Workability - Working with Purpleheart can present some unique challenges: if the wood is heated with dull tools, or if cutter speeds are too high, Purpleheart will exude a gummy resin that can clog tools and complicate the machining process. Depending on the grain orientation, can be difficult to plane without tearout. Purpleheart also has a moderate dulling effect on cutters. Due to high OIL content, can be difficult to glue properly, and surface preparation prior to gluing is recommended (SEE INDEX).

Finish - The best finishes for this wood are lacquer (simple and straight forward), and tung oil followed by polyurethane or a suitable varnish. This wood is highly chatoyant and both tung oil and lacquer cause spectacular effects.

Pricing +++

Sapele – Sapele is from Tropical Africa. Besides the common ribbon pattern seen on quartersawn boards, Sapele is also known for a wide variety of other  figured grain patterns, such as: pommele, quilted, mottled, wavy, beeswing, and fiddleback. Common uses include veneer, plywood, furniture, cabinetry, flooring, boatbuilding, musical instruments, turned objects, and other small wooden specialty items. Often used as a substitute for Mahogany.

figured grain patterns, such as: pommele, quilted, mottled, wavy, beeswing, and fiddleback. Common uses include veneer, plywood, furniture, cabinetry, flooring, boatbuilding, musical instruments, turned objects, and other small wooden specialty items. Often used as a substitute for Mahogany.

Workability - Sapele can be troublesome to work in some machining operations, (i.e., planing, routing, etc.), resulting in tearout due to its interlocked grain. It will also react when put into direct contact with iron, becoming discolored and stained. Sapele has a slight blunting effect on cutters, but it turns, glues, and finishes well.

Finishing - There's no definitive best finish for sapele. Simply sand up to 220 grit, and apply your favorite topcoat.

Pricing ++++

Snakewood (Letterwood, Amourette) - Snakewood is so called for its characteristic snakeskin patterns. The wood is typically a reddish brown, with cont rasting darker brown or black patches. The figuring can be so pronounced that it has been compared to the writing of hieroglyphics, and is sometimes called Letterwood. In addition to its colorful figure, Snakewood is also among the densest and hardest of all wood species worldwide. Among woodworkers, it vies with Lignum Vitae as the heaviest wood in the world. It grows in coastal regions of northeast South America.

rasting darker brown or black patches. The figuring can be so pronounced that it has been compared to the writing of hieroglyphics, and is sometimes called Letterwood. In addition to its colorful figure, Snakewood is also among the densest and hardest of all wood species worldwide. Among woodworkers, it vies with Lignum Vitae as the heaviest wood in the world. It grows in coastal regions of northeast South America.

Workability - Being closely related to Bloodwood, Snakewood shares many of the same working properties; namely, the wood is extremely dense, and has a pronounced blunting effect on cutters. Snakewood also tends to be quite brittle and can splinter easily while being worked. Despite the difficulties of working it, Snakewood turns well and finishes to a high polish.

Finishing - Traditional furniture finishes, like boiled linseed oil will give a nice satin sheen. Many thin coats applied will begin to build up. Shellac will stick to anything, it is often used between dissimilar finishes as a barrier coat. I use a " traditional flake shellac" dissolved in denatured alcohol. You can control how thin, or thick you make it. Very simple to make and to use, very forgiving. You could even alternate 1 coat linseed oil, 1 coat shellac. It would not take much to build a nice finish up on a wood that is as dense as you say. Keep the coats thin to give the best water resistance. In the future you can give it a fresh coat of either and it will look like new again.

Pricing ++++++ As a rare and small tree, prices for surfaced and milled Snakewood that display the characteristic snakeskin pattern are perhaps the most expensive of any exotic lumber worldwide in terms of per-boardfoot cost. Less figured sections of the wood are usually sold for much lower prices (under the name Amourette). Snakewood is also commonly sold in full and half log forms, which typically include significant pith checking and areas of both figured and non-figured wood, which can result in high wastage.

Teak – Native to southern Asia, Africa, and Latin America. Sometimes called Burmese Teak, this name is used to differentiate natural-grown trees (typically from Myanmar, aka Burma) from Teak grown on plantations. Used extensively in India and within its natural range for centuries, Teak has grown into a worldwide favorite. With its superb stability, good strength properties, easy workability—and most of all, its outstanding resistance to decay and rot—it's no wonder that Teak ranks among the most desired lumbers in the world. Common uses include ship and boatbuilding, veneer, furniture, exterior construction, carving, turnings, and other small wood objects.

from Myanmar, aka Burma) from Teak grown on plantations. Used extensively in India and within its natural range for centuries, Teak has grown into a worldwide favorite. With its superb stability, good strength properties, easy workability—and most of all, its outstanding resistance to decay and rot—it's no wonder that Teak ranks among the most desired lumbers in the world. Common uses include ship and boatbuilding, veneer, furniture, exterior construction, carving, turnings, and other small wood objects.

Workability - Easy to work in nearly all regards, with the only caveat being that Teak contains a high level of silica (up to 1.4%) which has a pronounced blunting effect on cutting edges. Despite its natural oils, Teak usually glues and finishes well, though in some instances it may be necessary to wipe the surface of the wood with a solvent prior to gluing/finishing to reduce the natural oils on the surface of the wood. Wear goggles, gloves and a respirator mask when sanding teakwood. Teakwood dust can irritate skin.

Finishing - Don't apply varnish or polyurethane to teakwood. Because teak's grain is oily and dense, varnish has a tendency to peel off. Apply teak oil or teak sealer to the dry, clean wood. Both products penetrate the surface grain for added protection from the elements. Brush on a thin coat with a natural bristle brush and let it soak in, or buff it with a soft buffing pad as directed on the product's label. Additional thin coats of oil or sealer can offer more protection and enhance surface luster.

Pricing ++++

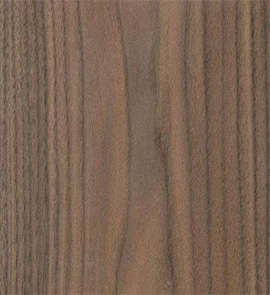

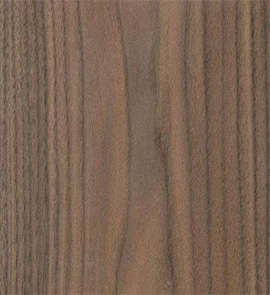

Walnut, Black – From Eastern United States. Heartwood can range from a lighter pale brown to a dark chocolate brown with darker brown streaks. Color c an sometimes have a grey, purple, or reddish cast. Black walnut is important for its attractive timber, which is hard, dense, tight-grained and polishes to a very smooth finish. When kiln-dried, walnut wood tends toward a dull brown color, but when air-dried can become a rich purplish-brown. Because of its color, hardness and grain, it is a prized furniture and carving wood. Veneer sliced from walnut burl is one of the most valuable and highly prized by cabinet makers and prestige car manufacturers. Walnut is also used by makers of stringed instruments such as the violin and guitar and for the body of pipe organs.

an sometimes have a grey, purple, or reddish cast. Black walnut is important for its attractive timber, which is hard, dense, tight-grained and polishes to a very smooth finish. When kiln-dried, walnut wood tends toward a dull brown color, but when air-dried can become a rich purplish-brown. Because of its color, hardness and grain, it is a prized furniture and carving wood. Veneer sliced from walnut burl is one of the most valuable and highly prized by cabinet makers and prestige car manufacturers. Walnut is also used by makers of stringed instruments such as the violin and guitar and for the body of pipe organs.

Workability - Typically easy to work provided the grain is straight and regular. Planer tearout can sometimes be a problem when surfacing pieces with irregular or figured grain. Glues, stains, and finishes well, (though walnut is rarely stained). Responds well to steam bending.

Finishing – oil-based varnishes

Pricing +

Tropical Walnut – (or Peruvian Walnut) Source trees are spread throughout Central America and the northern part of South America. Heartwood tends  to be darker than temperate walnut species, with a deep chocolate brown color, sometimes with a purplish hue. Tropical Walnut is more expensive than domestic species of Walnut.

While you won't find a lot of antique furniture in the U.S. made of Peruvian walnut, the wood has been used extensively in Central and South America for furniture and cabinetry. It also makes excellent interior trim, furniture, cabinetry, veneers, musical instruments, and flooring, though it is on the soft side for high traffic flooring.

to be darker than temperate walnut species, with a deep chocolate brown color, sometimes with a purplish hue. Tropical Walnut is more expensive than domestic species of Walnut.

While you won't find a lot of antique furniture in the U.S. made of Peruvian walnut, the wood has been used extensively in Central and South America for furniture and cabinetry. It also makes excellent interior trim, furniture, cabinetry, veneers, musical instruments, and flooring, though it is on the soft side for high traffic flooring.

Workability -

Typically easy to work provided the grain is straight and regular. Planer tearout can sometimes be a problem when surfacing pieces with irregular or figured grain.

Finishing - Glues, stains, and finishes well.

Pricing +++

Wenge - Wenge is a member of the great tree producing family, Leguminosae and comes from Zaire and other small countries of West Africa. The wood ha s excellent strength and hardness properties, and is also dark enough to be used as a substitute for ebony – it is nearly 100% black. Wenge is also marked with slightly lighter brown streaks which gives the wood an unusual, yet delightful, appearance. Wenge is hard and heavy, and makes a superb accent wood in highly decorative projects. It is a good wood for turning and is sliced for paneling and veneers for furniture and cabinets and musical instruments. It is listed as endangered due to a population reduction of over 50% in the past three generations, caused by a decline in its natural range, and exploitation.